Die Casting Molds vs. Plastic Molds: Which Offers Better Durability?

While choosing the ideal shape for assembling, the decision between Die Casting Mold and plastic mold is basic. Both enjoy particular benefits and are appropriate for various applications. This exhaustive aide dives into the subtleties of Die Casting Mold versus plastic molds, featuring their sturdiness and reasonableness for different enterprises.

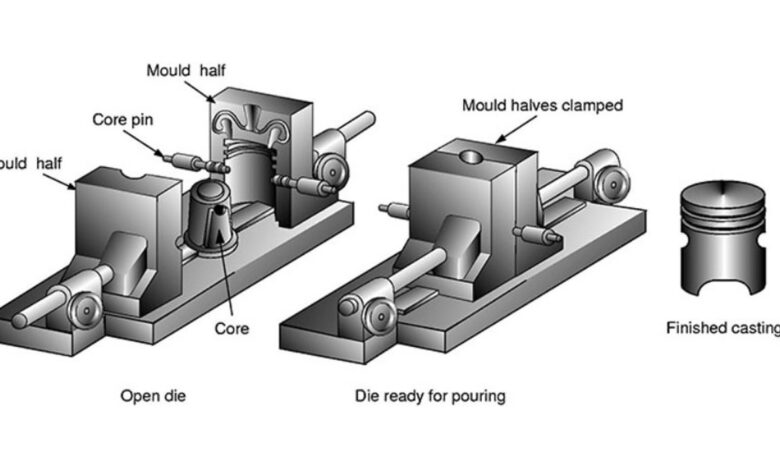

Understanding Die Casting Mold

Pass on projecting is an interaction that includes compelling liquid metal into a form under high tension. This procedure is prestigious for delivering exceptionally exact and complex metal parts. Here is a top to bottom gander at Die Casting Mold:

Creation and Plan

Pass on projecting molds are normally produced using high-strength steel or other solid metals. These molds are designed to endure the serious strain and temperature of the liquid metal. The development includes mind boggling plan work to guarantee that the form can deal with rehashed use without huge wear.

Sturdiness and Life span

Die Casting Mold are known for their extraordinary strength. The excellent materials and exact assembling processes add to their life span. These molds can persevere through a great many projecting cycles prior to requiring support or substitution. Their protection from wear and warm pressure makes them ideal for high-volume creation runs.

Applications

Die Casting Mold are dominatingly utilized in enterprises requiring vigorous and complex metal parts, for example, auto, aviation, and gadgets. The molds are appropriate for delivering parts with tight resistances and perplexing calculations.

Investigating Plastic Mold

Plastic mold, utilized in infusion forming, include infusing liquid plastic into a shape hole. This strategy is flexible and broadly utilized for creating plastic parts. How about we inspect the subtleties of plastic molds:

Sythesis and Plan

Plastic mold are frequently produced using aluminum, steel, or a blend of both. They are intended to oblige the cooling and warming cycles that plastic goes through during embellishment. The plan of these molds is less intricate contrasted with pass on projecting molds, yet expects accuracy to guarantee quality and consistency.

Toughness and Life span

While plastic mold are sturdy, they for the most part have a more limited life expectancy contrasted with Die Casting Mold. The molds experience wear from rehashed warm cycling and strain changes, which can prompt corruption over the long run. In any case, plastic molds are appropriate for moderate to high creation volumes and are less expensive to produce and keep up with.

Applications

Plastic molds are utilized in different businesses, including purchaser products, bundling, and clinical gadgets. They are great for delivering high-volume, minimal expense plastic parts with somewhat basic calculations.

Near Investigation: Die Casting Mold versus Plastic Molds

To figure out which shape type offers better solidness, we think about pass on projecting molds and plastic molds across a few measures:

Material and Interaction Appropriateness

Die Casting Mold: The most ideal for high-strength metals and complex plans. They succeed in applications requiring high accuracy and strength.

Plastic Molds: Reasonable for plastics and less complex plans. They are financially savvy for enormous creation runs of plastic parts.

Cost and Upkeep

Die Casting Mold: Higher introductory expense however lower support recurrence because of their vigorous development.

Plastic Molds: Lower starting expense however may require more regular support and substitution.

Creation Volume and Proficiency

Die Casting Mold: Ideal for high-volume creation with predictable quality and insignificant post-handling.

Plastic Molds: Viable for moderate to high creation volumes, offering adaptability in plan and material decision.

Life span and Wear Opposition

Die Casting Mold: Better life span and obstruction than wear because of high-strength materials and exact designing.

Plastic Mold: For the most part less tough however adequate for some applications with moderate creation prerequisites.

End

Both Die Casting Mold and plastic mold offer remarkable advantages relying upon the application. Pass on projecting mold give predominant toughness, life span, and accuracy, making them ideal for high-strength metal parts. Conversely, plastic molds offer expense benefits and adaptability, reasonable for a great many plastic parts.

Picking between bite the dust projecting and plastic forms eventually relies upon the particular necessities of the assembling system, including material, plan intricacy, and creation volume.